Engineering Projects

2D PIV Analysis of a Vortex Ring Passing Through a Coaxial Aperture

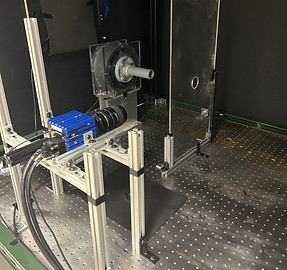

Led a research project focused on obtaining two-dimensional Particle Image Velocimetry (PIV) data to study the movement of a vortex ring through an axisymmetric coaxial aperture of comparable size. This research enabled the analysis of the hydrodynamic impulse enhancement that occurs when the vortex ring passes through the aperture, providing valuable insights into vortex dynamics and their impact on fluid flow. The project contributed to a deeper understanding of vortex behavior, with potential applications in aerodynamics and fluid-structure interactions.

CAD Final Design Project - String Trimmer Full Assembly

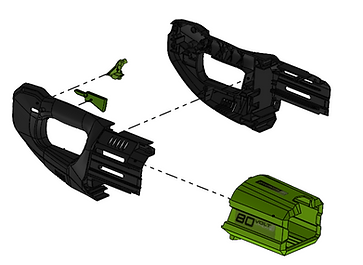

Collaborated in a team of five to fully model all components of an electric string trimmer using SolidWorks. My responsibilities included solid modeling, creating detailed assemblies, and generating dimensioned technical drawingsfor manufacturing. Additionally, I produced 3D visualizations using 3ds Max, including dynamic exploded-view animations to illustrate the assembly process and highlight component relationships.

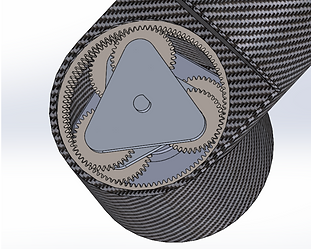

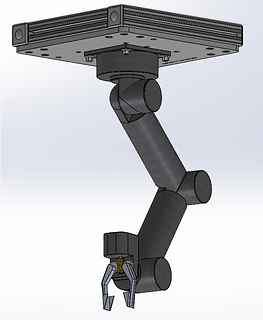

ARM (Automatic Regolith Sampling Mechanism)

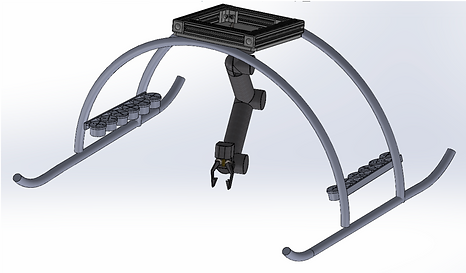

I contributed to the design of a quadcopter-based system for collecting surface regolith samples in Arctic and Antarctic regions. The system features a robotic arm with a gripper to collect both soil and rocks, and a helicopter-style skid landing gear for stability and durability. The arm places samples into jars mounted on the skids, with the design capable of holding up to 12 samples per trip. The system is remotely controlled and equipped with a camera and touch sensors for precise collection. Materials were selected to ensure reliable performance in harsh, low-temperature environments.

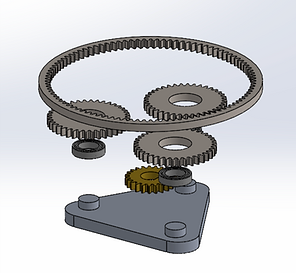

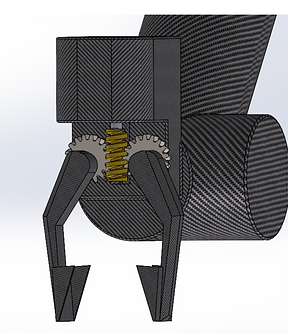

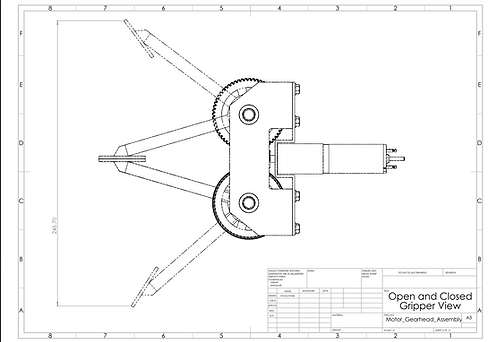

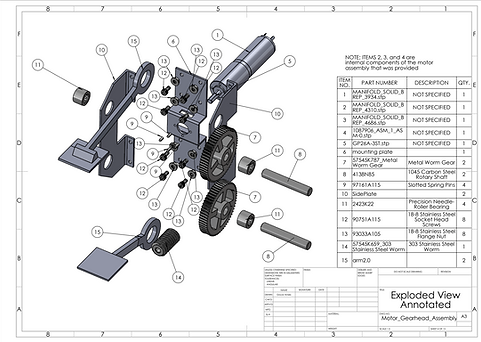

Robotic Gripping Mechanism

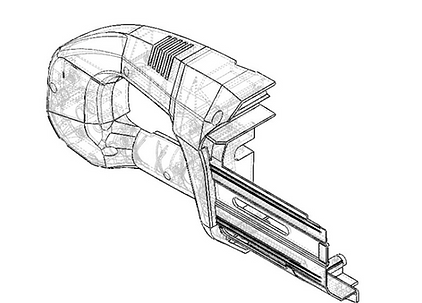

Designed an electrically actuated attachment in SolidWorks for my Machine Elements Final Class Project, ensuring it met specific functionality, weight, and size requirements. The design incorporated worm gears to convert rotational motion from a DC motor and planetary gearbox, enabling the device to effectively grip objects ranging from a sheet of paper to materials 0.1 meters thick. The project combined mechanical design principles with practical application to achieve optimal performance.

GD&T Roller Coaster Wheel Assembly

Designed a SolidWorks prototype of a wooden roller coaster wheel assembly, applying Geometric Dimensioning and Tolerancing (GD&T) to establish precise tolerance fits between key components: running wheels, side friction wheels, up-stop wheels, the wheel bogie, and the track. Key GD&T considerations included perpendicularity, hole dimensional tolerances, and cylindricity to ensure proper alignment and functionality. The prototype was constructed using a combination of 3D printed parts, off-the-shelf components, and scrap materials for a cost-effective and functional design.

Six Foot Wooden Bridge Competition

Applied mechanical engineering principles to design, refine, and test a wooden arch bridge constructed solely from 3/8" x 3/8" wooden members and wood glue. The bridge successfully supported a 500-pound load while weighing only 1.5 pounds. Through optimization of construction techniques and minimization of design redundancies, I improved the load-to-weight ratio and enhanced structural performance. This design earned first place for its efficiency and innovative approach.

Siesmic Tower Competition

Designed and constructed a 6-foot tall seismic tower using only 3/8" by 3/8" wood strips and wood glue to withstand randomized load distributions during an 8.0 magnitude earthquake simulation. The tower was engineered for optimal structural integrity and load distribution, ultimately achieving first place in the competition for its superior performance and innovative design